Products

HPS High Pressure Swing Clamp Cylinder

Product Overview

Swing clamp cylinders are typically used in applications where there is a need to maintain clear space for placing and clamping workpieces.

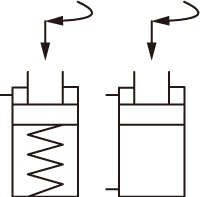

The clamping action of a swing Clamp cylinder consists of two parts (as shown in Figure 1). It first rotates to a specific angle and then lowers to clamp the workpiece. It's essential not to clamp the workpiece during the rotational stroke, as it can damage the internal rotational mechanism.

The swing clamp cylinders contains a clutch, which serves to separate the shaft and the internal rotational mechanism when the rotation speed is excessive, heavy clamping arm is installed, or when it collides with other objects during rotation. This is to protect the rotational mechanism from damage due to abnormal external forces.

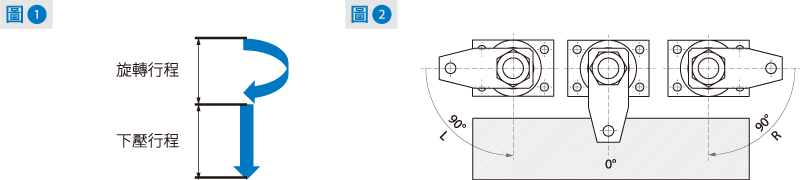

Swing clamp cylinders can be single-acting (with spring return) or double-acting, offering both clockwise and counterclockwise rotation. The standard rotation angle is 90°, with options for 60°, 45°, 30°, and 0° (as shown in Figure 2).

Installation methods include base mounting and full-threaded mounting.

You can choose pipe thread types or Manifold-Mounted Types.